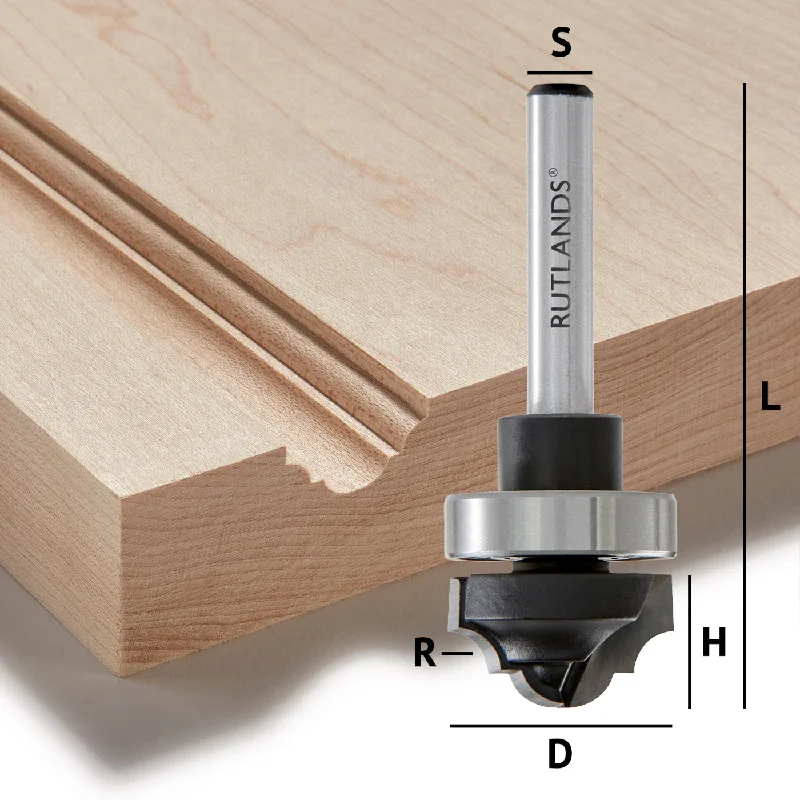

Router Bit - Plunge Classical Roman Ogee with Bearing - D=22mm H=12.7mm R=4mm L=59mm S=1/4"

Qty:

Each router bit features diamond ground, micro-grain tungsten carbide tipped blades. This tighter micro-grain structure means the blades offer long lasting hardness and superior edge retention. The body of each bit has been turned and then milled with uncompromising precision from a single piece of 4140 high tensile steel to give perfect balance for reduced vibration and therefore smoother cuts. 4140 steel has been chosen because of its toughness, high fatigue strength, and abrasion and impact resistance. The tungsten carbide tips are then brazed onto the bodies using induction to create an extremely strong joint that safely holds under the high stresses that occur when routing. The router bits are suitable for use on softwoods, hardwoods, veneers, laminates and composite materials.

Plunge Classical Roman Ogee Bits

Plunge classical roman ogee bits are used to produce decorative furniture and panel moulding. The cutting edge of these bits extends across the base, allowing them to be used within a plunge router to produce grooves across the face of material. The shank mounted top bearing guide allows the bit to follow templates mounted on the surface of the workpiece. These bits feature a roman ogee profile with a stepped edge, or fillet, separating the convex and concave curves and a further fillet along the top edge. When used on the front of cabinet doors or drawers, these bits give panels a raised appearance. Shallow passes will produce a roundover panel mould, whereas deeper cuts will produce a classical profile. It is recommended that the template used is 5mm thicker than the cutting height (H) of the bit.

Superior Finish and Performance

The shearing angle of the cutting edges ensure they remain in constant contact with the workpiece to allow a smoother, slicing cut which eliminates tear-out and gives a mirror finish. The bits feature right hook angles which further enhances the cut due to the fast removal of chips. These bits feature an anti-kickback design which limits the feed rate of the material being cut to decrease the likelihood of a kickback, meaning each bit conforms to strict German DIN standards to ensure maximum operator safety. ©