demonstration video.

TCT Router Bits

Each router bit features diamond ground, micro-grain tungsten carbide tipped blades. This tighter micro-grain structure means the blades offer long lasting hardness and superior edge retention. The body of each bit has been turned and then milled with uncompromising precision from a single piece of 4140 high tensile steel to give perfect balance for reduced vibration and therefore smoother cuts. 4140 steel has been chosen because of its toughness, high fatigue strength, and abrasion and impact resistance. The tungsten carbide tips are then brazed onto the bodies using induction to create an extremely strong joint that safely holds under the high stresses that occur when routing. The router bits are suitable for use on softwoods, hardwoods, veneers, laminates and composite materials.

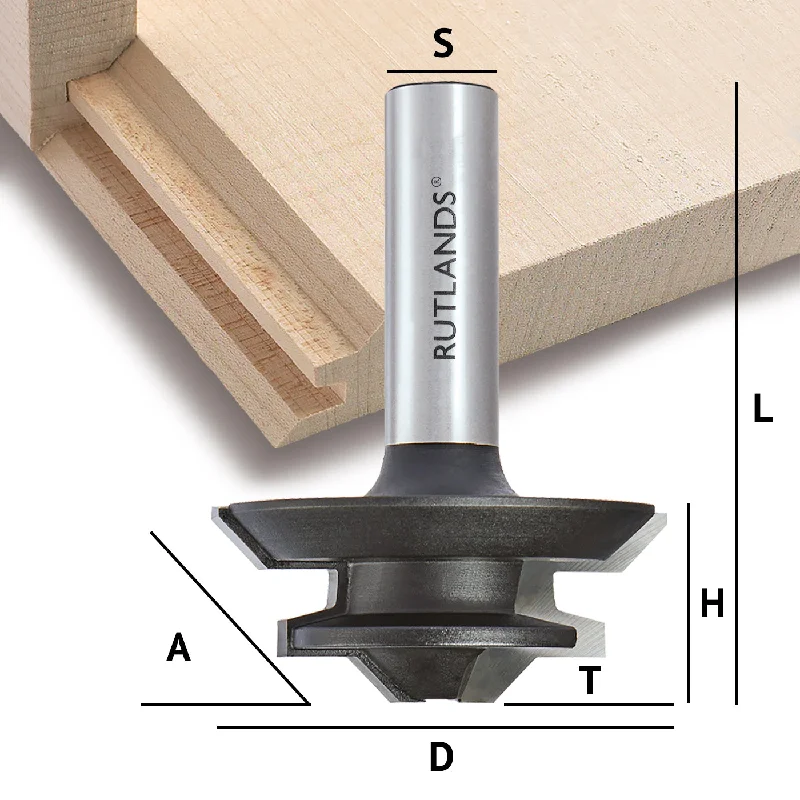

Lock Mitre Bits

Lock mitre bits create an interlocking profile which locks the joint against movement when clamped and gives a large surface area for gluing for guaranteed strength. The bits can be used to create perfect 90° corner joints as well as producing the joint needed for edge jointing boards together. To create a 90° joint one workpiece should be routed horizontally on the table while the other is routed vertically against the fence. These lock mitre bits are most commonly used for constructing boxes, drawers, and cabinet parts in addition to edge jointing boards. The bits have minimum and maximum timber widths as follows: R5728 - 9mm to 13mm, R5729 - 10mm to 18mm, R5730 - 13mm to 25mm. For router table use only.

Superior Finish and Performance

The shearing angle of the cutting edges ensure they remain in constant contact with the workpiece to allow a smoother, slicing cut which eliminates tear-out and gives a mirror finish. The bits feature right hook angles which further enhances the cut due to the fast removal of chips. These bits feature an anti-kickback design which limits the feed rate of the material being cut to decrease the likelihood of a kickback, meaning each bit conforms to strict German DIN standards to ensure maximum operator safety. ©